2025 Door and Window Rollers and Window Locks: Core Component Technology Upgrades Accelerate

In 2025, door and window rollers and window locks will become the focus of industry technological innovation, achieving key breakthroughs in durability and safety to meet new demands for large windows and passive house applications.

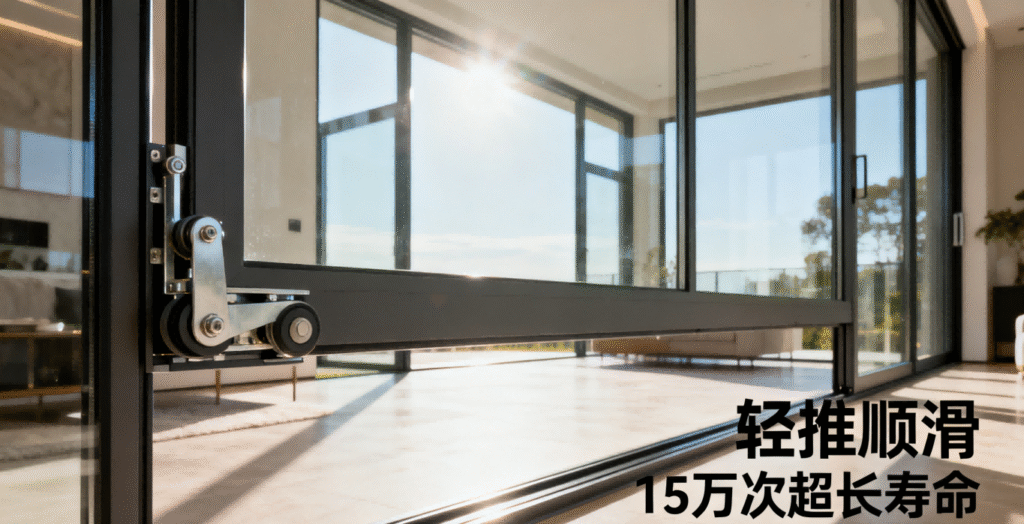

Rollers: High load-bearing capacity and long life become mainstream.

The application of new materials is driving a leap in roller performance. Glass-fiber-reinforced nylon and carbon fiber composite products offer 30% greater wear resistance than traditional materials, extending their weather resistance range to -40°C to 80°C. The German aluPilot series rollers can support up to 300kg per set, supporting large window sashes. Structurally, the “multi-ball bearing + sealed cavity” design reduces the friction coefficient to 0.02, extending the service life to 150,000 opening and closing cycles. Some silent and energy-saving models also help reduce the heat transfer coefficient of doors and windows, complying with passive house standards.

Window Locks: Double Upgrades in Security and Scene Adaptability

Window locks have evolved from simple locking to multi-dimensional protection. The triple structure of “hardened alloy steel lock tongue + anti-pry lock body + sensor alarm” is now standard in high-end products, improving pry resistance by 50%. At the same time, niche product categories have exploded. Elderly-friendly window locks have added a one-touch emergency call function, high-rise window locks are equipped with a stopper to prevent falling, and models designed for children’s rooms feature a design to prevent accidental opening, meeting diverse residential safety needs.