HAOTUO: Elevating Aluminum Door & Window Hardware Manufacturing with 11 Years of Expertise and Innovation

With 11 years of industry experience, HAOTUO has cultivated a reputation for delivering top-tier aluminum door and window accessories. Our 3,000-square-meter factory is a hub of technological advancement, where a seasoned R&D team and mature development technologies converge to create products that meet the most stringent global standards.

Step into our newly designed exhibition area, and you’ll find a space that mirrors our brand’s identity. The sleek, modern interiors, highlighted by clean lines and a sophisticated color palette, reflect the precision and reliability of our hardware solutions. From the moment you enter, the HAOTUO logo stands as a testament to our dedication to quality, while the product display zones—like our specially curated section for sliding door hardware—showcase the breadth and depth of our offerings. Every component, every design detail in these spaces is a nod to our expertise in crafting hardware that balances functionality, durability, and aesthetic appeal.

Our R&D team, a cornerstone of our success, continuously pushes the boundaries of innovation. Leveraging years of accumulated technical expertise, we develop customized solutions that address the unique needs of markets worldwide. Whether it’s enhancing the energy efficiency of window fittings or optimizing the smooth operation of door hardware, our team’s ingenuity ensures HAOTUO remains at the forefront of industry trends.

We invite global partners, distributors, and industry enthusiasts to explore HAOTUO’s world of aluminum door and window hardware. Discover how our 11 years of experience, state-of-the-art factory, and innovative R&D capabilities can elevate your projects. Join us as we continue to redefine excellence in the hardware manufacturing landscape.

HAOTUO—Where Precision Meets Innovation, For Over a Decade.

New door and window hardware handles are hot sellers in the Moroccan market, with diverse designs tailored to local architectural needs.

This series of handles includes classic colorways like black and white, as well as various styles like seven-shaped handles and round handles. Made of durable metal with a meticulously treated surface, they offer both rust resistance and aesthetics. Some handles can be used with lock cylinders for anti-theft protection, while others accommodate doors and windows with different opening methods, meeting the diverse door and window hardware needs of local residential and commercial buildings in Morocco

The Moroccan market has always focused on practicality and adaptability in its demand for door and window hardware. This batch of handle products not only conforms to local aesthetics in terms of appearance and design, but also adapts to common door and window profiles in Morocco in terms of structure. They are easy to install and stable in use. Therefore, they quickly gained market share upon their launch and became the preferred accessories for local door and window manufacturers and building materials distributors, demonstrating the competitiveness of Chinese door and window hardware products in the overseas market.

Participation in Dubai World Trade CentreNew Breakthroughs in Door and Window Roller Technology in 2025: High-Load-Bearing, Quiet Rollers Become the New Market FavoriteParticipation in Dubai World Trade Centre

Empowered by new materials, rollers will achieve both increased load-bearing capacity and durability.

The key breakthroughs in the roller industry in 2025 will be concentrated in material innovation. Leading companies will generally adopt glass-reinforced nylon + carbon fiber composites, which offer over 30% greater wear resistance than traditional nylon. Combined with graphene coating technology, these rollers are weather-resistant in extreme temperatures ranging from -40°C to 80°C, maintaining stable performance in environments ranging from humid coastal areas to freezing northern temperatures.

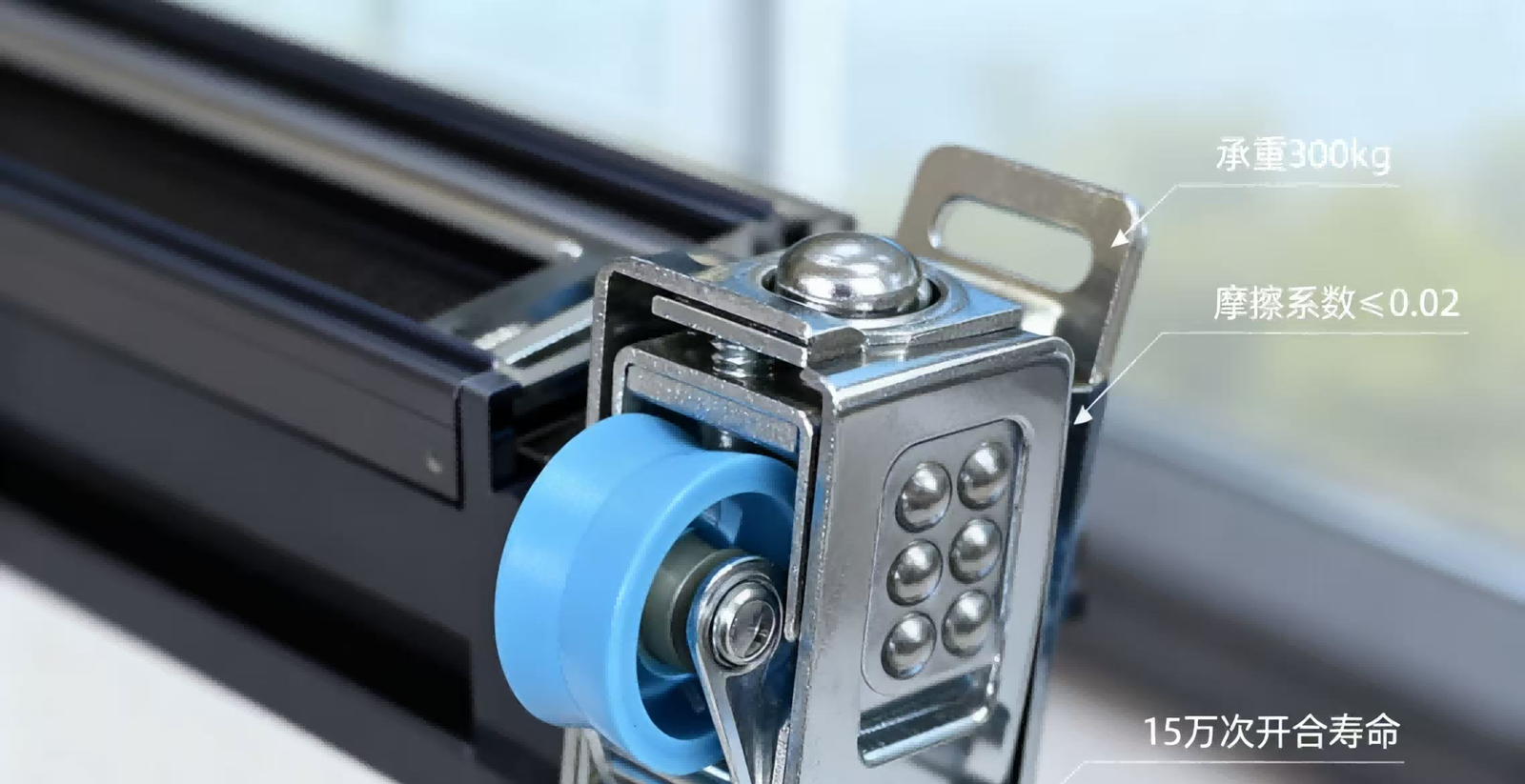

The high-end roller series launched by a German brand can support up to 300kg per set, easily supporting large glass sashes. The alloy bearing rollers developed by a local company, through a combination of metal and polymer materials, combine load-bearing performance with quiet operation. Their penetration rate in villa and high-end apartment projects has rapidly increased to 45%.

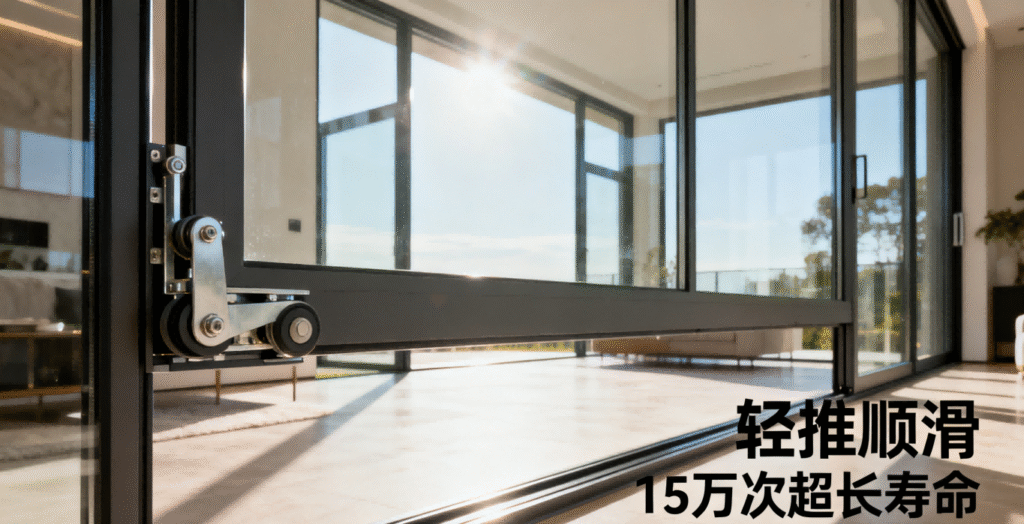

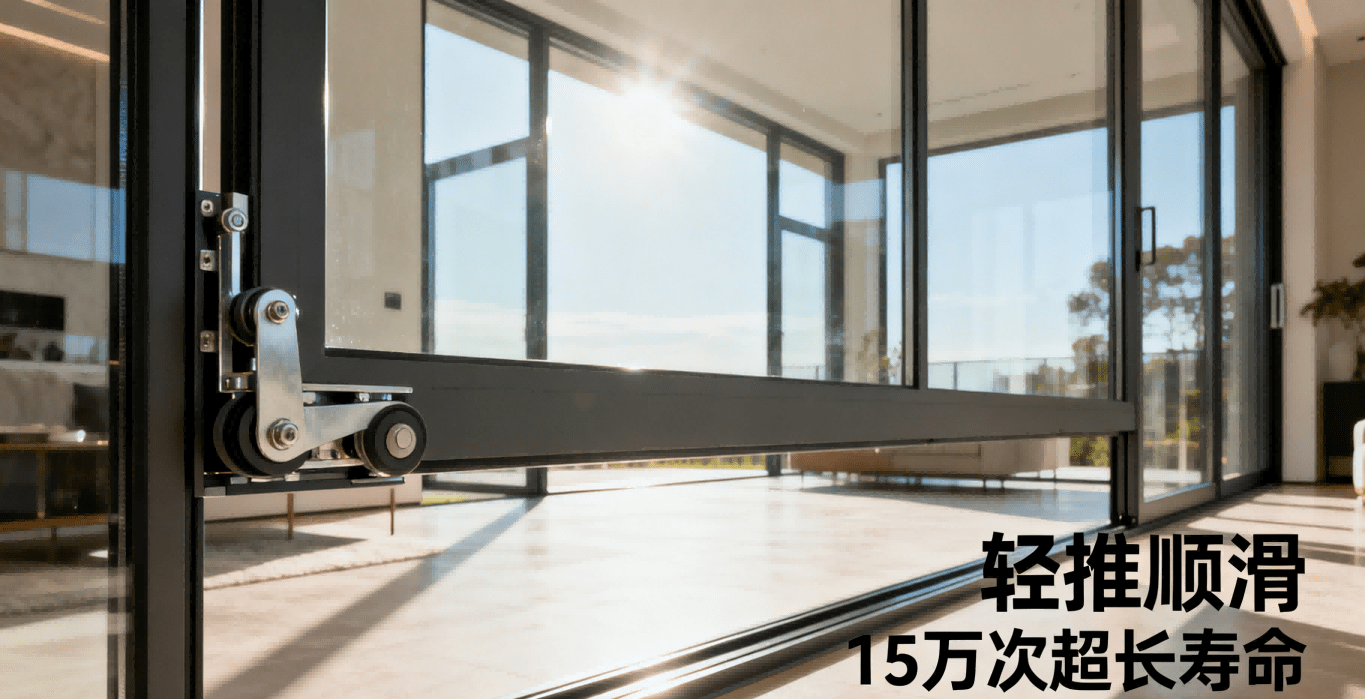

Structural Optimization Achieves “Easy Push, Smooth Slide + Long-Term Durability”

Optimizing the roller’s structural design is key to enhancing the user experience. Mainstream products utilize a “multi-ball bearing + sealed cavity” structure, reducing the coefficient of sliding friction to below 0.02. Even heavy sashes weighing 150kg can achieve a smooth “easy push, open” feel. The sealed cavity design effectively blocks dust and rainwater intrusion, extending the roller’s service life to over 150,000 opening and closing cycles, double that of traditional products.

To address energy conservation needs, some companies have introduced “silent, energy-saving rollers.” These utilize a special damping structure to reduce sliding vibration and air leakage through gaps. Combined with door and window sealing systems, they can reduce the overall heat transfer coefficient (K value) by 0.3W/(m²·K), making them a standard component of passive buildings.

Market demand is diverging, and customized rollers are emerging as a new growth point.

Diversified consumer demand is driving the shift toward scenario-based customization in roller products. “Quick-install roller kits” for renovating older homes feature a punch-free design, enabling quick installation in one hour. Sales are expected to exceed 8 million units by 2025. “High-temperature-resistant rollers” for sunrooms, with a special material formula that maintains stable performance even at temperatures up to 60°C, are expected to see a 35% year-on-year increase in market size.

Diversified consumer demand is driving the shift toward scenario-based customization in roller products. “Quick-install roller kits” for renovating older homes feature a punch-free design, enabling quick installation in one hour. Sales are expected to exceed 8 million units by 2025. “High-temperature-resistant rollers” for sunrooms, with a special material formula that maintains stable performance even at temperatures up to 60°C, are expected to see a 35% year-on-year increase in market size.

2025 Door and Window Rollers and Window Locks: Core Component Technology Upgrades Accelerate

In 2025, door and window rollers and window locks will become the focus of industry technological innovation, achieving key breakthroughs in durability and safety to meet new demands for large windows and passive house applications.

Rollers: High load-bearing capacity and long life become mainstream.

The application of new materials is driving a leap in roller performance. Glass-fiber-reinforced nylon and carbon fiber composite products offer 30% greater wear resistance than traditional materials, extending their weather resistance range to -40°C to 80°C. The German aluPilot series rollers can support up to 300kg per set, supporting large window sashes. Structurally, the “multi-ball bearing + sealed cavity” design reduces the friction coefficient to 0.02, extending the service life to 150,000 opening and closing cycles. Some silent and energy-saving models also help reduce the heat transfer coefficient of doors and windows, complying with passive house standards.

Window Locks: Double Upgrades in Security and Scene Adaptability

Window locks have evolved from simple locking to multi-dimensional protection. The triple structure of “hardened alloy steel lock tongue + anti-pry lock body + sensor alarm” is now standard in high-end products, improving pry resistance by 50%. At the same time, niche product categories have exploded. Elderly-friendly window locks have added a one-touch emergency call function, high-rise window locks are equipped with a stopper to prevent falling, and models designed for children’s rooms feature a design to prevent accidental opening, meeting diverse residential safety needs.

Green Innovation and Local Breakthroughs Lead Global Market Restructuring

Greening: Full-chain Innovation Reshapes the Industry

By 2025, green will become the core competitiveness of the window and door accessories industry. The proportion of corporate environmental protection investment will leap from 8% in 2020 to 25%, forming a complete green ecosystem encompassing “material innovation, low-carbon production, and recycling,” driving the industry’s transformation from “high-consumption manufacturing” to “sustainable manufacturing.”

In the field of material innovation, breakthroughs have been made. Polymer composites, boasting a 35% increase in strength over traditional aluminum alloys and a 98% recyclability rate, have become the mainstream choice for high-end door and window hardware. Bio-based alloys have 72% lower carbon emissions than stainless steel and are weather-resistant to extreme temperatures ranging from -40°C to 70°C, making them widely used in outdoor sunrooms and high-rise residential projects. Nano-ceramic coating technology extends the corrosion life of vulnerable components such as hinges and rails to 30 years, doubling the traditional process. Energy-saving performance has also been significantly improved, with the heat transfer coefficient (K value) of mainstream thermal insulation hardware systems dropping below 0.7W/(m²·K). Over 60% of leading companies’ products meet the highest international passive house standards.

The low-carbon transformation on the production side has also achieved remarkable results: 75% of the world’s large-scale enterprises have completed clean energy substitution, and the integrated photovoltaic production base has reduced energy consumption per unit of output value by 45%; the penetration rate of “zero wastewater” treatment technology has exceeded 80%, and 92% of metal waste has been recycled through the reverse logistics network; the modular production model not only reduces production waste by 30%, but also shortens the delivery cycle of small-batch customized orders to 5-8 days, taking into account both environmental protection and efficiency.