Participation in Dubai World Trade CentreNew Breakthroughs in Door and Window Roller Technology in 2025: High-Load-Bearing, Quiet Rollers Become the New Market FavoriteParticipation in Dubai World Trade Centre

Empowered by new materials, rollers will achieve both increased load-bearing capacity and durability.

The key breakthroughs in the roller industry in 2025 will be concentrated in material innovation. Leading companies will generally adopt glass-reinforced nylon + carbon fiber composites, which offer over 30% greater wear resistance than traditional nylon. Combined with graphene coating technology, these rollers are weather-resistant in extreme temperatures ranging from -40°C to 80°C, maintaining stable performance in environments ranging from humid coastal areas to freezing northern temperatures.

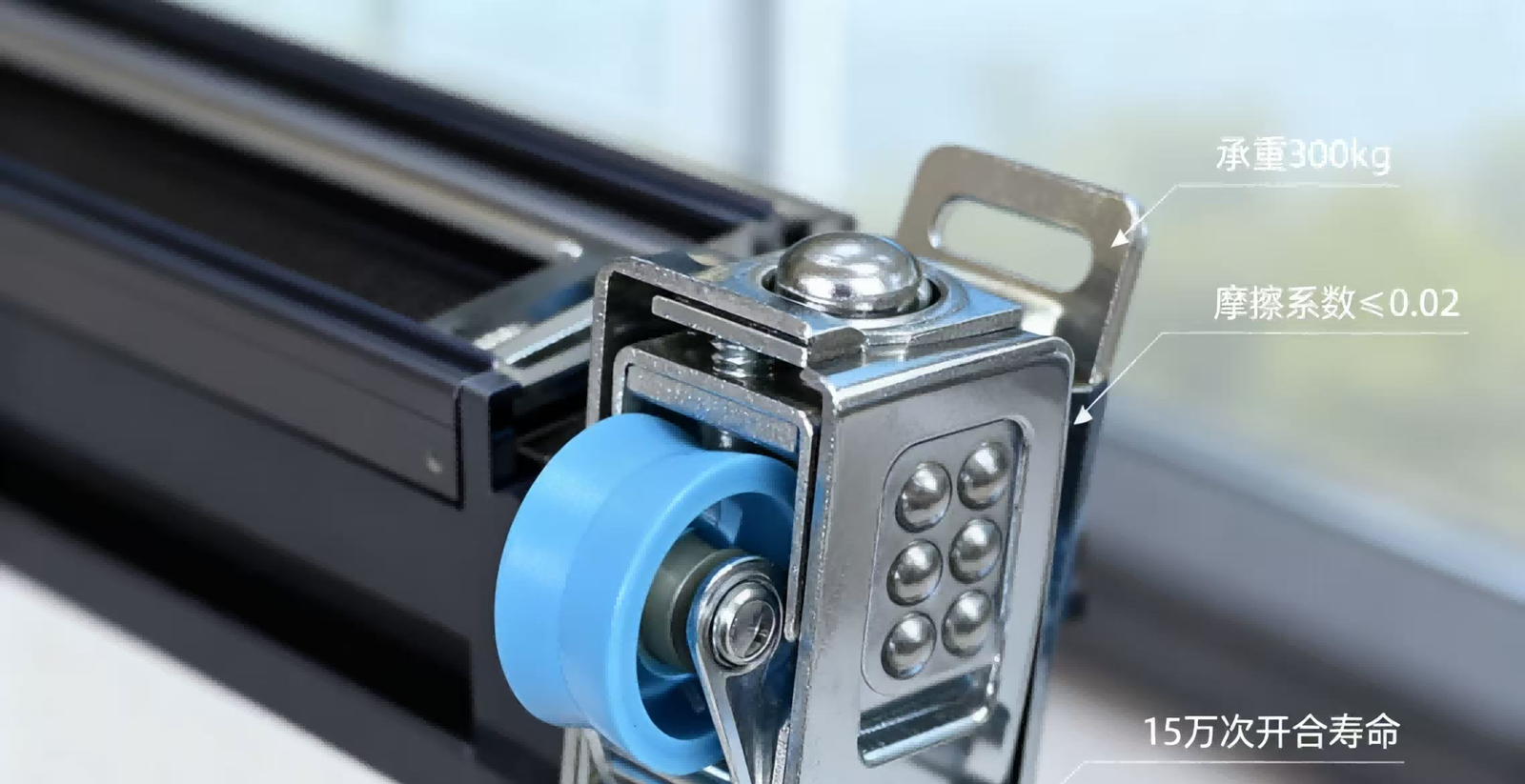

The high-end roller series launched by a German brand can support up to 300kg per set, easily supporting large glass sashes. The alloy bearing rollers developed by a local company, through a combination of metal and polymer materials, combine load-bearing performance with quiet operation. Their penetration rate in villa and high-end apartment projects has rapidly increased to 45%.

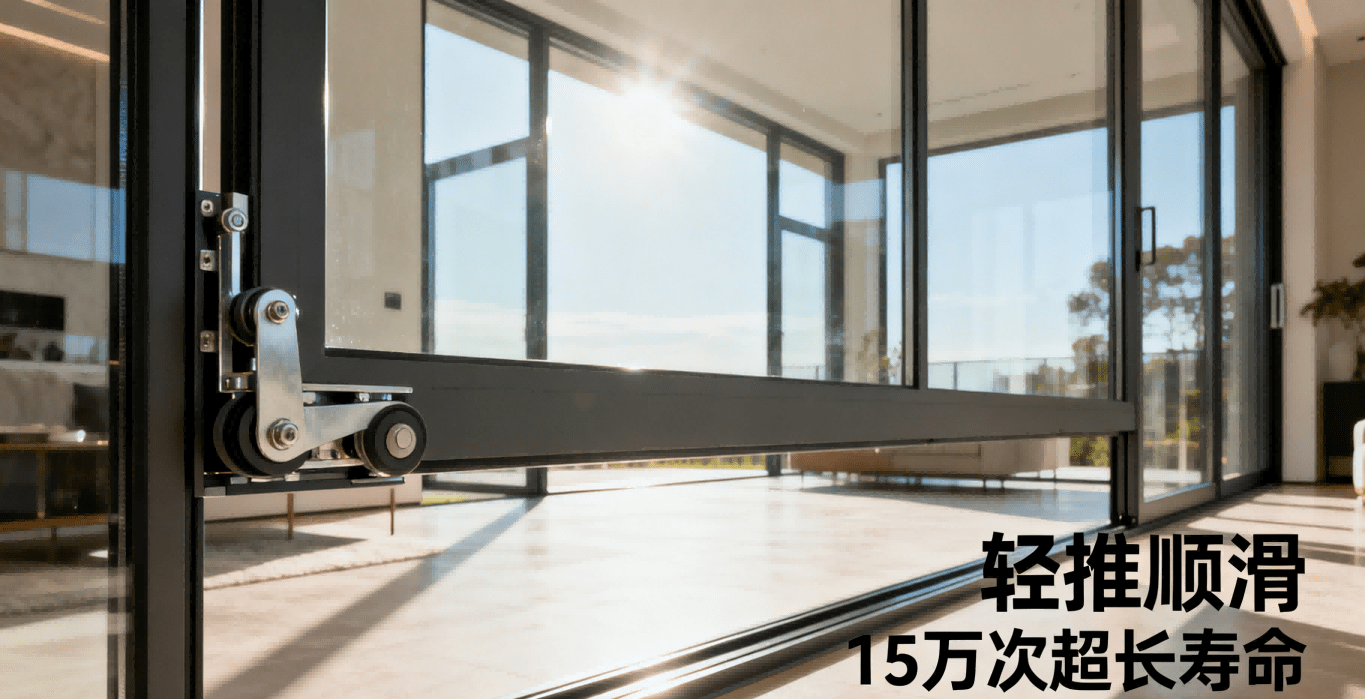

Structural Optimization Achieves “Easy Push, Smooth Slide + Long-Term Durability”

Optimizing the roller’s structural design is key to enhancing the user experience. Mainstream products utilize a “multi-ball bearing + sealed cavity” structure, reducing the coefficient of sliding friction to below 0.02. Even heavy sashes weighing 150kg can achieve a smooth “easy push, open” feel. The sealed cavity design effectively blocks dust and rainwater intrusion, extending the roller’s service life to over 150,000 opening and closing cycles, double that of traditional products.

To address energy conservation needs, some companies have introduced “silent, energy-saving rollers.” These utilize a special damping structure to reduce sliding vibration and air leakage through gaps. Combined with door and window sealing systems, they can reduce the overall heat transfer coefficient (K value) by 0.3W/(m²·K), making them a standard component of passive buildings.

Market demand is diverging, and customized rollers are emerging as a new growth point.

Diversified consumer demand is driving the shift toward scenario-based customization in roller products. “Quick-install roller kits” for renovating older homes feature a punch-free design, enabling quick installation in one hour. Sales are expected to exceed 8 million units by 2025. “High-temperature-resistant rollers” for sunrooms, with a special material formula that maintains stable performance even at temperatures up to 60°C, are expected to see a 35% year-on-year increase in market size.

Diversified consumer demand is driving the shift toward scenario-based customization in roller products. “Quick-install roller kits” for renovating older homes feature a punch-free design, enabling quick installation in one hour. Sales are expected to exceed 8 million units by 2025. “High-temperature-resistant rollers” for sunrooms, with a special material formula that maintains stable performance even at temperatures up to 60°C, are expected to see a 35% year-on-year increase in market size.